Environmentally conscious exhaust air purification in foil production

Pure air and heat recovery

Whether it is for packaging, bin liners or coatings – the foil manufacturing industry serves a wide variety of target markets. But as large as the variety of different products may be, so complex is the exhaust air pollution in production plants. The highly specialized manufacturing processes require a custom-made exhaust air solution, as — in addition to legal requirements — companies are setting themselves increasingly ambitious pure air quality targets: for their employees, the environment and for cost reasons.

Customized exhaust air solutions for highly specialized manufacturing processes

The different production processes in foil manufacturing — e.g. casting, calendering or blow molding — are all facing the same problems: How can efficient, cost-effective and precisely fitted exhaust air purification be implemented in accordance with legal and in-house requirements?

For more than 60 years, the exhaust air expert KMA Umwelttechnik has been advising companies on solutions for exactly this question. The innovative modular system of the KMA exhaust air filtration systems is custom-made for the requirements of the customer and production plants.

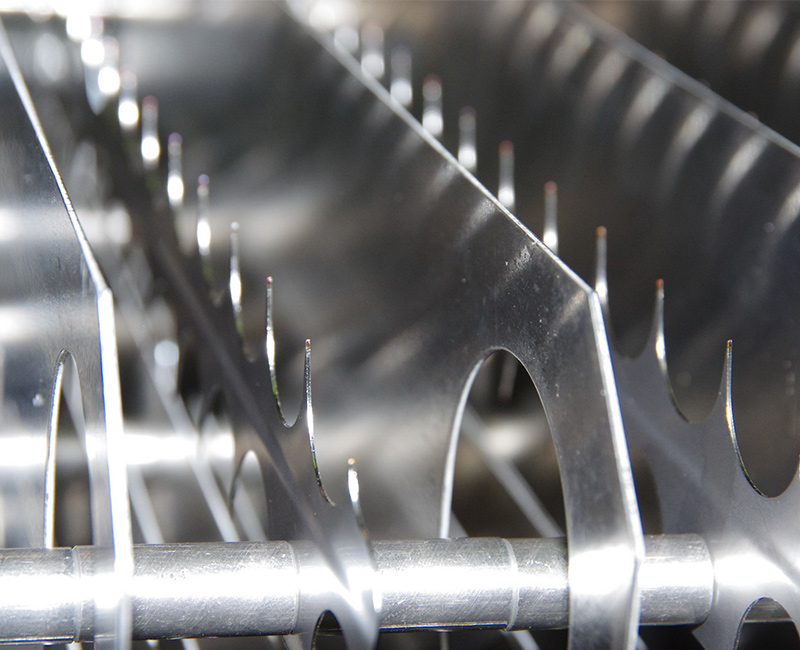

The heart of the KMA exhaust air filtration system is the KMA electrostatic precipitator. Each electrostatic precipitator consists of numerous precipitator cell, each of which consists of an ionization electrode and several collector plates. Inside the precipitator cell, the ionization electrode generates a strong electrical field requiring only a very low energy input. Impurities in the incoming exhaust air are electrically charged and driven to the collector plates. Especially the environmentally and health damaging plasticizer fumes and oily aerosols — omnipresent in the plastics industry — are thus reliably removed from the exhaust air. The KMA electrostatic precipitator is combined with a decentralized extraction system directly at the emission source to ensure a precisely fitting exhaust air collection. This can be a custom-made KMA exhaust hood or a precisely fitting, individually adapted extraction unit. Depending on the application, KMA’s high-performance exhaust air purification systems achieve a separation efficiency of up to 99 %.

This makes KMA a cost-efficient and durable alternative to conventional exhaust air purification systems such as thermal oxidation systems or scrubbers. The use of the automatic KMA filter cleaning system (CIP) eliminates the need for a costly replacement of the filtration medium, which further contributes to the long service life of KMA exhaust air purification systems.

Efficient heat recovery in foil extrusion

Foil production is a very heat-intensive process, as large amounts of thermal energy are required and released at many points in the production process. Whether it is the plasticizing of raw materials, the extrusion of foil tubes or the cooling and stretching of foil webs. All these production steps require thermal energy and in turn release it back into the production exhaust air.

Using an innovative heat recovery system, this valuable resource can be made usable once more. KMA combines its powerful exhaust air purification system with an efficient heat exchanger. If required, this system can be extended by the efficient KMA Ambitherm® thermal heat pump.

This realizes cost reductions and, at the same time, minimizes the carbon footprint of the company.

Reduced odor — made possible with the KMA exhaust air purification system

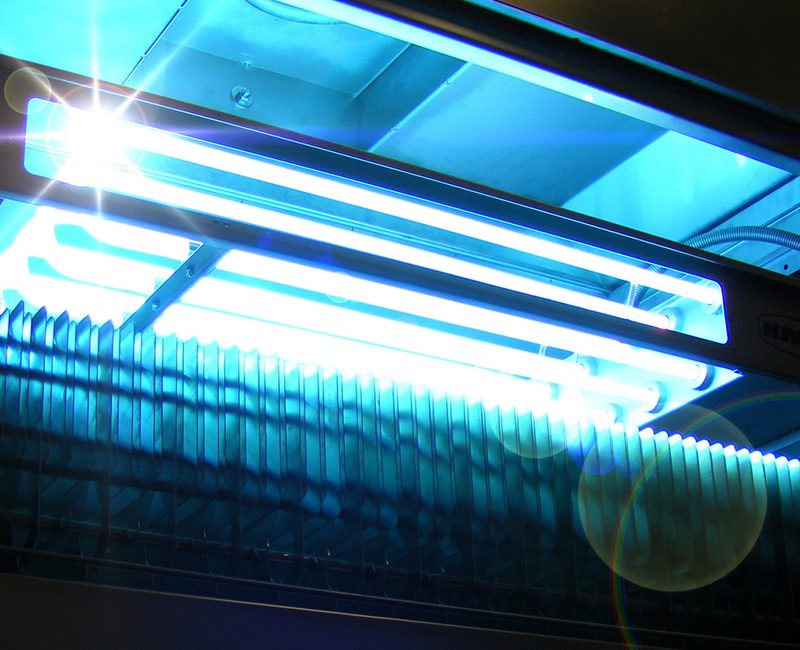

In addition to the separation of impurities and the optional heat recovery, KMA exhaust air filtration systems also offer the possibility of comprehensive odor separation. KMA relies on its innovative UV light module and the powerful activated charcoal filter.

For a comprehensive odor separation, the purified exhaust air stream is led through the KMA UV light module after the KMA electrostatic precipitator. Here, osmophoric aerosols, mists and vapors are neutralized using photo-oxidation and the exhaust air stream is then passed through a reaction path. This reaction tunnel is then followed by a purification through the KMA activated charcoal filter. Based on the adsorption principle, the activated charcoal filter removes osmophoric molecules from the exhaust air stream by depositing them on the porous surface of the activated carbon.

The UV light module is cleaned by the automatic KMA filter cleaning system (CIP) just like the demister, electrostatic precipitator and heat exchanger.

Powerful exhaust air purification for various products:

The KMA exhaust air purification system is suitable for the following film groups, among others:

- Polyethylene foils (PE-foils)

- Polypropylene foils (PP foils)

- Polyvinyl chloride foils (PVC foils)

- Polystyrene foils (PS-foils)

- Polyester Foils

Our expert for exhaust air purification and high-grade heat recovery in film production

Hannes Berteit

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Press articles

Download Brochure

Advantages of the KMA exhaust air purification concept:

- The precisely fitting filter design allows for high energy efficiency

- The automatic filter cleaning system (CIP) enables a time and cost effective cleaning of all system components

- Filtration without performance loss as a cost-effective and energy-efficient alternative to conventional exhaust air purification systems, such as thermal oxidation or gas scrubbers.

- Meets the requirements of current national and regional environmental protection regulations

- Modular design for individual and custom-made combination with modules for odor separation and heat recovery

- High-quality stainless steel construction for low material wear and long service life without costly replacement of filtration elements.

KMA ULTRAVENT® – modular und flexible

KMA ULTRAVENT® is a modular exhaust air purification system consisting of the following filter modules:

The KMA ULTRAVENT® demister cells consist of stable 50 mm thick stainless steel wire meshes, which are fixed on the inlet and outlet side by an expanded metal mesh. The special rolling of the wire enables high separation efficiency of aerosols, droplets and mists. The cells can be cleaned by washing them out. An exchange of the demister cells is not necessary.

The powerful KMA electrostatic precipitator removes even finest particles, oily and pasty aerosols, vapours or mist – without sticking or pressure loss. The filter consists of numerous filter cells, each consisting of an ionizer and several collector plates. The impurities bound in the incoming exhaust air are electrostatically charged and driven to the collector plates. With the help of the fully automatic filter cleaning system (CIP), the filter module is freed from the filter cake and cleaned at regular intervals. This eliminates the need for costly filter replacement. KMA electrostatic precipitators are characterized by their high efficiency and long service life.

The KMA modular filter system offers a wide range of mechanical filter cells for almost any application. The mechanical filter cells of KMA Umwelttechnik can be used as pre-filters (filter class G), as high-performance main filters (filter class F) and as HEPA filters (filter class H) with high separation efficiency.

For a time and energy efficient recovery of valuable process waste heat, KMA Umwelttechnik uses its innovative parallel heat recovery system. The KMA heat recovery system consists of the effective KMA heat exchanger and – depending on the application and customer requirements – the powerful KMA Ambitherm® heat pump. The recovered heat can then be fed back into the product cycle and used for other purposes. The KMA heat recovery system is part of the KMA exhaust air purification system and is therefore also cleaned at regular intervals by the automatic filter cleaning system (CIP).

The innovative KMA UV light module is an elementary component of the separation of intensive odorous VOC molecules. This is done by photooxidation, which results in a significant improvement of the odour load. Depending on the odour load of the exhaust air stream, the KMA UV light module enables a complete odour separation.

In addition to the KMA UV light module, KMA also uses the KMA activated carbon filter for the separation of odorous vapors, mists or aerosols. Here, the odour-bearing molecules are deposited on the porous surface. The KMA activated carbon filter is installed downstream of the KMA electrostatic precipitator to achieve an optimal cleaning result.

KMA uses its innovative KMA exhaust gas scrubber for a comprehensive separation of odorous aerosols, gases, vapors or mists. This works according to the absorption principle, with the help of a suitable washing liquid the impurities are bound and separated. In combination with the KMA electrostatic precipitator or the mechanical filter from KMA, the KMA exhaust gas scrubber achieves a high separation efficiency with low water consumption.

The automatic KMA exhaust air purification system CIP (“cleaning in place”) is an elementary part of the KMA exhaust air purification concept for many applications. The cleaning of the filter cleaning system CIP does not only include the KMA Electrostatic Precipitator, but also attached filter components such as the KMA UV light module or the KMA heat exchanger.

The KMA filter cleaning system uses a movable nozzle block and thus guarantees an unmatched cleaning result. It can be programmed fully automatically and individually – for regular cleaning without high personnel expenditure. The intelligent control system ensures low consumption of washing water and cleaning agents. This greatly reduces the maintenance effort for the entire exhaust air cleaning system.